Quality control is the process of fulfilling and checking the conformance to quality standards. There are many different approaches to quality control, but an important part of every one of these is regular inspection of the goods. Besides dedicated QMS software, some ERP/MRP systems offer the required functionality to small businesses.

You can also listen to this article:https://www.podbean.com/player-v2/?i=r7r7j-126015b-pb&from=pb6admin&share=1&download=1&rtl=0&fonts=Arial&skin=1&font-color=&logo_link=episode_page&btn-skin=3

- What is Quality Control?

- Quality Control vs. Quality Assurance

- Benefits of Quality Control

- Quality Control methods and methodologies

- Quality Control in ERP/MRP

- Key takeaways

What is Quality Control?

Quality control (QC) is the process of fulfilling quality standards, checking the products’ conformance to them, and improving product quality as a consequence. As such, it is a vital part of materials management. Much of a company’s quality control activity is made up of inspections where physical products are visually examined in order to detect inconsistencies.

These inspections may include batch inspection, product sampling, laboratory testing, etc.

Although the employees that inspect the products are directly responsible for the quality of the goods, proper quality control is not only confined to inspections. Quality control approaches such as ISO 9001 also put a strong emphasis on areas that support quality management such as process management, competence building, organizational culture, etc.

Quality Control vs. Quality Assurance

While quality control deals with fulfilling quality requirements and checking the conformance of the goods, quality assurance (QA) is tasked with creating the conditions for fulfilling the quality requirements. Quality control is therefore focused on the product while quality assurance is process-oriented.

For example, quality assurance activities include process documentation, auditing, supplier management, personnel training, production engineering, etc.

That means quality assurance is rather proactive and aims to create a system that would manufacture high-quality products while quality control is tasked with checking if that has been achieved.

Benefits of Quality Control

There are many benefits to having quality control procedures in place, with the most obvious advantage being improved quality in the workplace. Some of the additional benefits gained with QC are:

- Achieving regulatory compliance

- Greater customer satisfaction

- More effective use of resources

- Streamlined processes

- Reduced production costs

- Increased profits

Quality Control methods and methodologies

There are many different quality control methodologies that have found widespread use in both large and small businesses. Ranging from simple inspections to using statistical tools or quality control charts, these approaches help companies track, analyze, and reduce inconsistencies.

100% inspection method

As the name already says, the core idea of the 100% inspection method is to inspect each and every item in a stock lot. While this method is very effective in detecting inconsistencies in the quality of the goods, it is also more costly than a sample inspection. The 100% inspection method only pays off when the cost of accepting defective products is very high, when you are sure that a batch contains defective goods, when a production employee is prone to making mistakes, or when you know that the supplier is not ensuring good quality in their facility.

Acceptance sampling method

Acceptance sampling is based around randomly inspecting only a certain amount of items in a stock lot. If the quantity of defective items in the sample is low, the whole lot is accepted. If the amount of defects is high, however, the whole lot is rejected. This way, however, a possibility remains that bad decisions will be made so when a mistake could prove to be very expensive, the 100% inspection method would be a better option.

Statistical quality control (SQC)

Statistical quality control (SQC) is a quality control system that employs statistical methods to monitor the quality in a facility. It uses sampling inspections, data analysis, and control charting to determine the probability of defects, allowing you to investigate the root causes and improve quality.

Statistical process control (SPC)

Statistical process control (SPC) is another process and quality monitoring methodology that employs statistics to detect inconsistencies in the facility. SPC uses tools such as cause and effect diagrams, control charts, defect mapping, etc. in order to improve quality and efficiency, reduce waste, and instill continuous improvement practices.

Total quality management (TQM)

Total quality management (TQM) is a methodology that aims to produce goods that would satisfy customers in the most economical way. As such, it is a much wider approach than SQC, encompassing all areas of business from product design to customer service, with the objective of putting continuous improvement practices in place that would lead to ever-increasing customer satisfaction.

Six Sigma

Six Sigma is a modern quality management methodology that aims to eliminate variance from business and manufacturing processes. A Six Sigma process is supposed to be consistent, with no defects occurring 99.99966% of the time – that makes 3.4 defective occurrences in every million. The methodology revolves around identifying and eliminating variance through a process of steps called DMAIC:

- Define the problem

- Measure current performance

- Analyze the process and find the root cause of variations

- Improve the process by eliminating the root cause

- Control the improved process to avoid falling back

In product design, these steps are sometimes also referred to as DMADV or Define, Measure, Analyze, Design, Verify.

Six Sigma is generally better suited for larger companies, having been implemented by many Fortune 500 companies among others. But it can be implemented in smaller businesses as well – it may cost a lot, though.

Lean Six Sigma

Lean Six Sigma is an amalgamation of the philosophies and methodologies of lean manufacturing and Six Sigma. It therefore aims to eliminate variation in processes as well as the eight types of waste that are at the center of the lean philosophy. That makes Lean Six Sigma a lot more extensive than Six Sigma as besides defects, the implementation also targets overproduction, wait time, non-utilized talent, inefficient transportation, excessive inventory, unnecessary movements, and excessive processing. It is safe to say, therefore, that Lean Six Sigma is not merely a quality control methodology, but rather an overall approach to management.

Quality Control in ERP/MRP

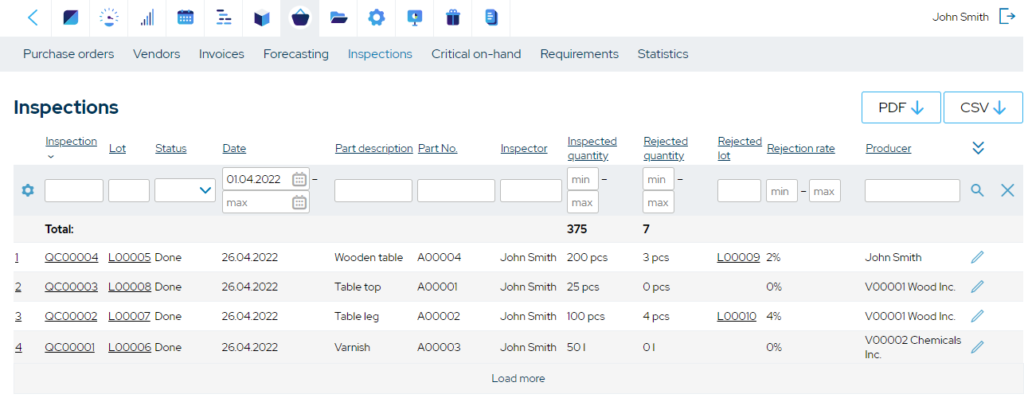

While there are many different quality management (QMS) software available on the market that provide manufacturers with advanced functionality for quality monitoring, these are often too expensive and complicated for smaller businesses. Especially when there are other types of software deployed that need to be implemented, utilized, and paid for. Instead, some ERP/MRP systems offer basic quality monitoring along with lot tracking functionality in their packages, bringing the overall costs of software down while providing small businesses with simple tools to improve their manufacturing processes and the quality of their products.

This basic quality control functionality should include:

- Quality inspection settings for both procured and manufactured goods

- Approved items automatically becoming available in stock

- Service orders (rework/repair) or write-offs available for rejected items

- Notifications for items to be inspected

- Statistics such as total rejection rates, and rejection rates per supplier or per employee

These features are already a great jumping-off point when trying to improve the quality in your facility without complicating your workflows with very complex quality management software. Most ERP/MRP systems for SMEs lack these functionalities, however, so it is necessary to make sure the software you choose fits the needs of your company.

Key takeaways

- Quality control (QC) is the process of fulfilling quality standards, checking the products’ conformance to them, and improving product quality as a consequence.

- On the other hand, quality assurance (QA) is tasked with creating the conditions for fulfilling the quality requirements. Quality control is therefore focused on the product while quality assurance is process-oriented.

- There are many different approaches to QC, with some of the more popular methodologies being statistical quality control (SQC), statistical process control (SPC), total quality management (TQM), Six Sigma, and Lean Six Sigma.

- Every approach, however, is based around the regular inspection of goods.

- Although there are many dedicated quality management software, these are often too expensive and complex for smaller businesses. Fortunately, some ERP/MRP systems offer the required functionality for quality monitoring.